The circular economy for lead batteries provided by highly regulated recyclers in many regions delivers the ultimate sustainability goal of creating much needed energy storage solutions from waste.

However, this does not apply everywhere and unsound recycling practices can result in lead and other hazardous substances causing environmental and human health damage where the informal sector operates.

Sub-Saharan Africa is one such region where economic growth has resulted in growing vehicle fleets, high demand for backup power systems and decentralised solar installations that are increasing the volumes of used lead batteries. These batteries are often collected by hundreds of small collectors and sold on to the informal sector or regulated recyclers operating without taking the kind of precautions necessary to avoid pollution. There are currently very few environmentally sound lead battery recyclers operating in Sub Saharan Africa.

Typically lead batter recyclers in low and middle income countries (LMICs) are often small and investment costs required to make them environmentally sound can be substantial and make operating facilities uneconomic. Often the technical knowledge required to develop a plant in an environmentally sound and profitable way is lacking. And there is little enforcement of often inadequate regulations.

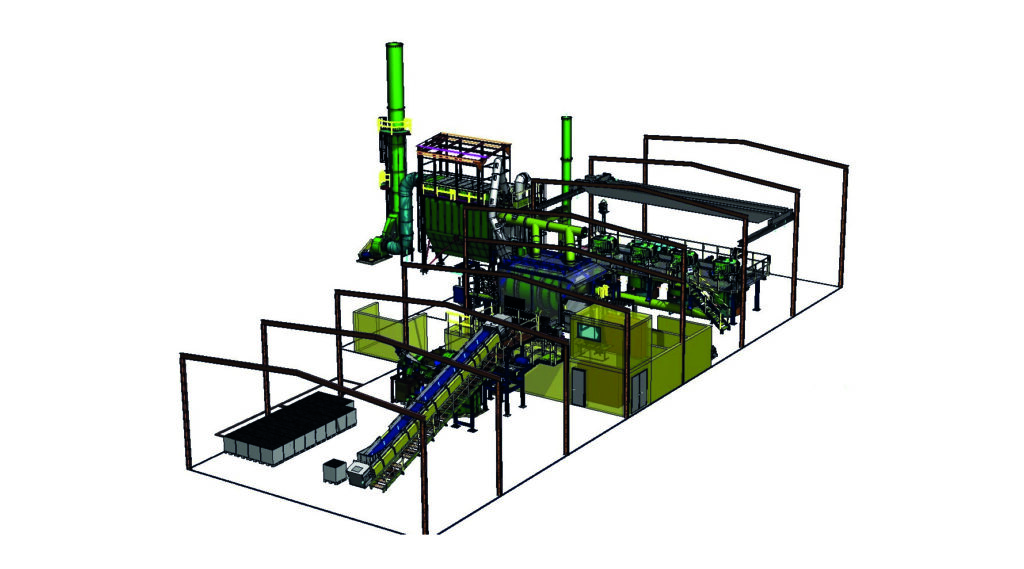

ILA member company Engitec Technologies, has addressed this by developing an innovative new modular engineering solution – called CX® SMART – that includes a breaking and separation station, foundry and refinery, ingot caster and pollution control system that can process up to 12,000 tonnes per year of waste lead batteries. It is a perfectly-sized solution for a typical LMIC.

The first installation of the new system is scheduled to take place in the Ivory Coast in 2025 at a coastal location that will facilitate export of the battery grade lead to countries that require it for battery manufacturing. Engitec will provide hands on support during the commissioning and ongoing operation of the facility to ensure that it maximises recovery of lead and minimises emissions of hazardous substances to the environment. With support from the local policy makers to develop and enforce binding minimum standards for recyclers operating in the region, the commissioning of this new plant will bring social and economic benefits to the Ivory Coast and ensure that its waste lead batteries can be recovered to produce a saleable product without the cost of pollution to human health and the environment.

Dr Steve Binks, ILA’s Senior Director for Regulatory Affairs said: “Finding solutions to the problem of poor lead battery recycling practices is often challenging but the new innovative offering, developed specifically for adoption in LMICs by Engitec, offers some hope the UNEA-Resolution on improving lead-acid battery recycling (UNEA/EA.3/Res.9) can be achieved.”

The two 3D drawings display different views of the complete Engitec CX® Smart Plant.